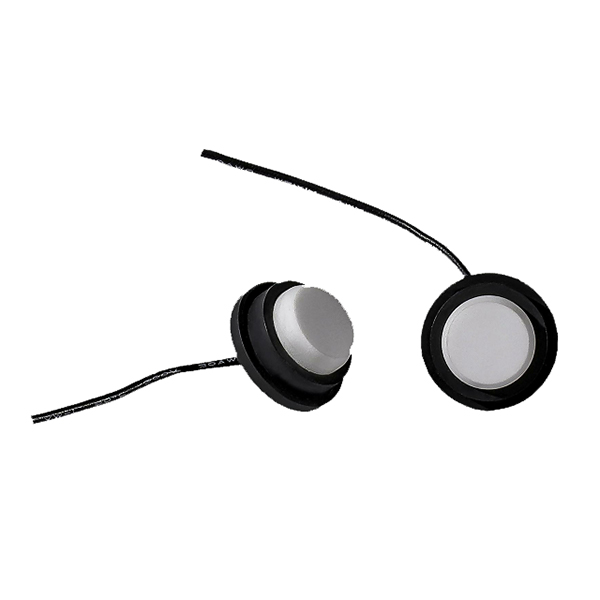

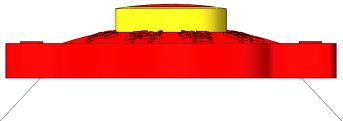

I-Valve yokuphepha yokuzivala yepayipi

Indawo yokufaka

Ivalvu ezivalayo ingafakwa epayipini legesi phambi kwesitofu noma isifudumezi samanzi.

Izinzuzo Zomkhiqizo

Isici nezinzuzo ze-Pipeline zokuzivikela ezivikelekile

1.Ukubekwa uphawu okuthembekile

2.ukuzwela okuphezulu

3.impendulo esheshayo

4.ivolumu encane

5.akukho ukusetshenziswa kwamandla

6.Kulula ukufaka nokusebenzisa

7.Impilo ende

8.I-interface ingenziwa ngezifiso

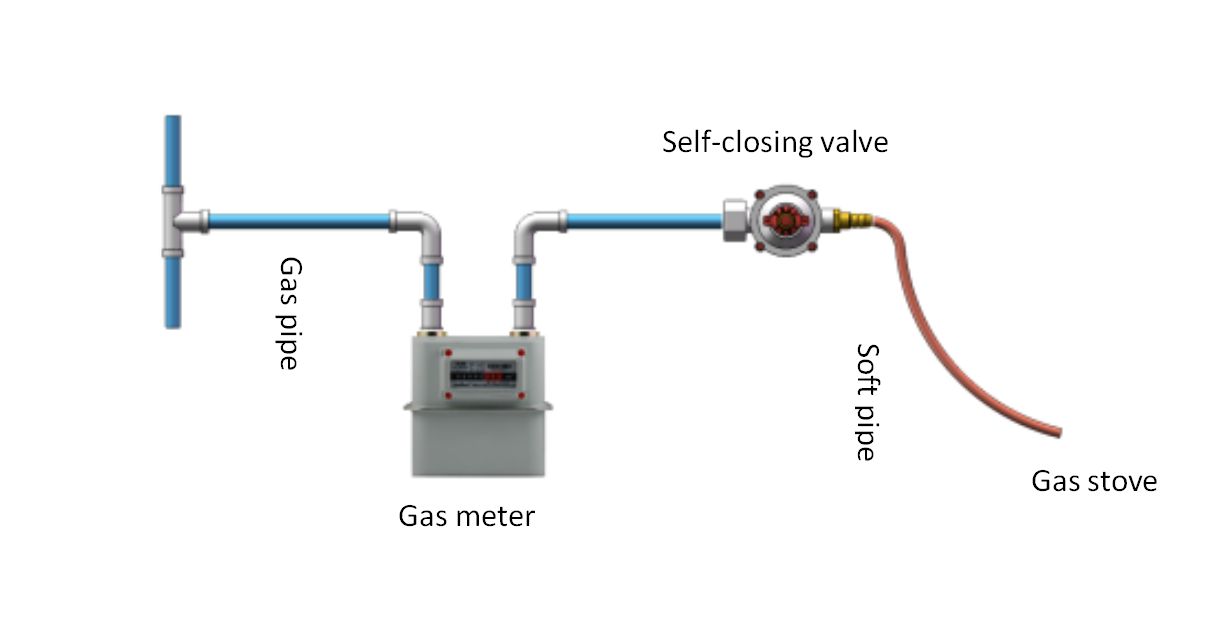

Isingeniso somsebenzi

Ukuvalwa okuzenzakalelayo kokucindezela ngokweqile

Uma isilawuli somfutho esisekupheleni kwephayiphi legesi sisebenza ngendlela engavamile noma umfutho wepayipi uphezulu kakhulu ngenxa yokuhlolwa komfutho wepayipi okwenziwa inkampani yegesi, ivalvu izovalwa ngokuzenzakalelayo ngoba umfutho wepayipi ungaphezu kwenani elibekiwe ukuvimbela ipayipi ukuthi lingavuzi futhi linqanyulwe ngenxa yomfutho wepayipi ophezulu.

Ukuvalwa okuzenzakalelayo ngaphansi kwengcindezi

Lapho isilawuli somfutho esisekupheleni kwepayipi legesi singejwayelekile, ngesikhathi sokusetshenziswa kwegesi okuphezulu kakhulu, ipayipi legesi livinjwa yiqhwa, ukushoda kwegesi ebusika, ukumisa igesi, ukushintshwa, kanye nokusebenza kokunciphisa ingcindezi, amapayipi angaphandle alinyazwa izinhlekelele zemvelo ezenziwe umuntu noma ezinye izivalo eziphuthumayo zasendlini zivaliwe. Uma umfutho wegesi uphansi kunevelu ebekiwe noma ukunikezwa kwegesi kuphazamiseka, i-valve izovala ngokuzenzakalelayo ngoba umfutho wepayipi uphansi kunevelu ebekiwe ukuvimbela izingozi zegesi ngenxa yokuvuza.

Ukuvala okuzenzakalelayo okuchichimayo

Uma inkinobho yomthombo wegesi kanye nesilawuli sengcindezi esisekupheleni kwephayiphi legesi kungavamile, noma ipayipi leraba liyawa, liguga, noma ligqabuke, ipayipi le-aluminium-plastic kanye nepayipi lensimbi kugqwalile ngogesi futhi kubhoboke, ukushintsha kokucindezeleka kuyaqhekeka. , ukuxhuma kukhululekile, futhi umpheki wegesi awujwayelekile, okubangela ukuba igesi elisepayipini igcwale. Uma ukucindezela kulahleka, i-valve ingavalwa ngokuzenzakalelayo ukuze iphazamise ukunikezwa kwegesi.

Umyalelo Wokusetshenziswa

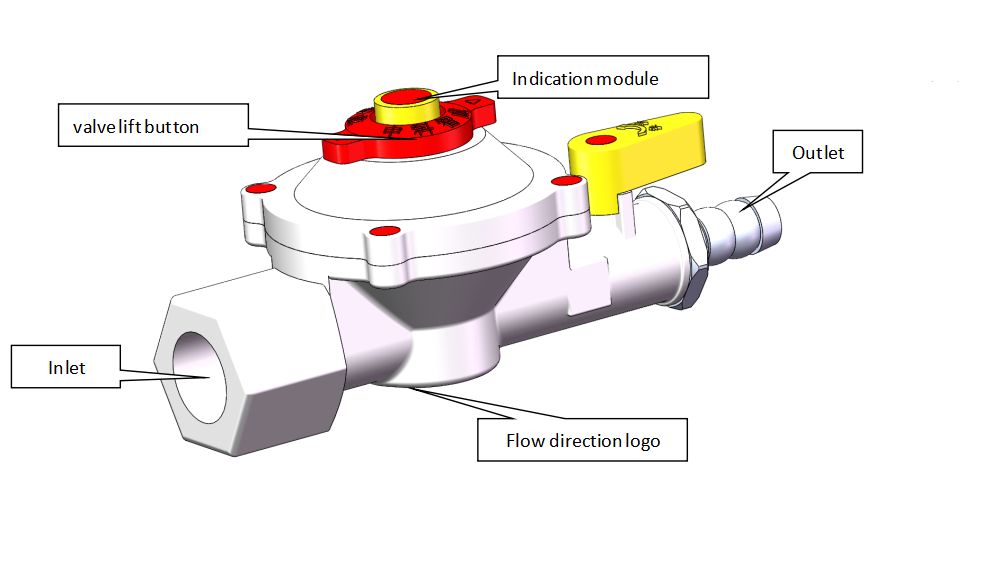

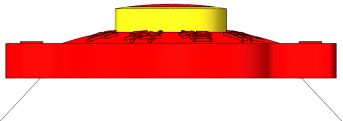

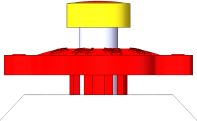

Ivalufu isimo sokuqala sokuvala

isimo esijwayelekile sokusebenza

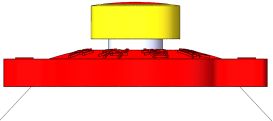

Ukuzivala kwe-undervoltage noma okwedlulele

ukuzivala ngokucindezela ngokweqile

1. Esimweni esivamile sokunikezwa kwegesi, phakamisa ngobumnene inkinobho yokuphakamisa i-valve phezulu (vele uyiphakamise kancane, ungasebenzisi amandla amaningi), i-valve ingavulwa, futhi inkinobho yokuphakamisa izosethwa kabusha ngokuzenzakalelayo ngemva kokuyikhulula. Uma inkinobho yokuphakamisa ingasethwa kabusha ngokuzenzakalelayo, sicela ucindezele ngesandla inkinobho yokuphakamisa ukuze uyisethe kabusha.

2. Isimo esivamile sokusebenza se-valve siboniswa emfanekisweni. Uma udinga ukuphazamisa ukunikezwa kwegesi kumshini wegesi ngesikhathi sokusebenzisa, udinga kuphela ukuvala i-valve yezandla ekugcineni kwe-valve. Akuvunyelwe ukucindezela imodyuli yenkomba ngesandla ukuze uvale ngokuqondile i-valve;

3. Uma kutholakala ukuthi i-module yenkomba yehla futhi ivala i-valve ngesikhathi sokusetshenziswa, ibonisa ukuthi i-valve ingene ngaphansi kwe-voltage noma isimo sokuzivala samanje (njengoba kuboniswe esithombeni). Abasebenzisi bangakwazi ukuzihlola ngokwabo ngezizathu ezilandelayo. Ezinkingeni ezingakwazi ukuxazululwa ngokwazo, kufanele zixazululwe yinkampani yegesi. Ungayixazululi uwedwa, izizathu ezingaba zimi kanje:

(1) Ukuphazamiseka kokuphakelwa kwegesi noma umfutho wamapayipi uphansi kakhulu;

(2) Inkampani yegesi yamisa igesi ngenxa yokulungiswa kwemishini;

(3) Amapayipi angaphandle alinyazwa yizinhlekelele zemvelo ezenziwe abantu;

(4) Okunye ngaphakathi endlini Ivalvu yokuvala izimo eziphuthumayo ivaliwe ngenxa yezimo ezingavamile;

(5) ipayipi lenjoloba liyawa noma into esebenza ngegesi ingavamile (njengokuvuza komoya okubangelwa ukushintsha okungavamile);

4.Uma kutholakala ukuthi imodyuli yenkomba ikhuphukele endaweni ephakeme kakhulu ngesikhathi sokusetshenziswa, ibonisa ukuthi i-valve isesimweni sokucindezela ngokweqile nokuzivala (njengoba kuboniswe esithombeni). Umsebenzisi angakwazi ukuzihlola ngezizathu ezilandelayo futhi akuxazulule ngenkampani yegesi. Ungayixazululi uwedwa, bese ucindezela phansi ngemva kokuxazulula inkinga Imojula yenkomba ibuyisela i-valve esimweni sokuqala esivaliwe, futhi i-valve ingavulwa ngokuphakamisa inkinobho ye-valve futhi. Izizathu ezingenzeka zokuvala ingcindezi ngokweqile yilezi ezilandelayo:

(1)Isilawuli sengcindezi esisekupheleni kwephayiphi legesi sisebenza ngendlela engavamile;

(2)Inkampani yegesi yenza umsebenzi wamapayipi. Umfutho wepayipi uphezulu kakhulu ngenxa yokuhlolwa kwengcindezi;

5.Ngesikhathi sokusetshenziswa, uma uthinta ngephutha imojula yenkomba futhi ubangela ukuthi i-valve ivale, udinga ukuphakamisa inkinobho ukuze uvule kabusha i-valve.

I-Tech Specs

| Izinto | Ukusebenza | Izinga Lereferensi | |||

| Indawo yokusebenza | Igesi yemvelo,Igesi yamalahle |

| |||

| Ukugeleza okulinganiselwe | 0.7 m³/h | 1.0 m³/h | 2.0 m³/h | I-GB/T 6968-2011 | |

| Ingcindezi yokusebenza | 0~2kPa |

| |||

| Isebenzaizinga lokushisa | -20℃~60℃ |

| |||

| Izinga lokushisa lesitoreji | -20℃~60℃ |

| |||

| Umswakama | 5%~90% |

| |||

| Ukuvuza | Hlangana ne-CJ ejwayelekile/T 447-2014 | CJ/T 447-2014 | |||

| Closingisikhathi | ≤3s |

| |||

| Ingcindezi yokuzivala ngokweqile | 8±2kPa |

| |||

| Ingcindezi yokuzivala engaphansi kwengcindezi | 0.8±0.2kPa |

| |||

| Ukugeleza okuzivalayo okuchichimayo | 1.4m³/h | 2.0m³/h | 4.0m³/h | ||

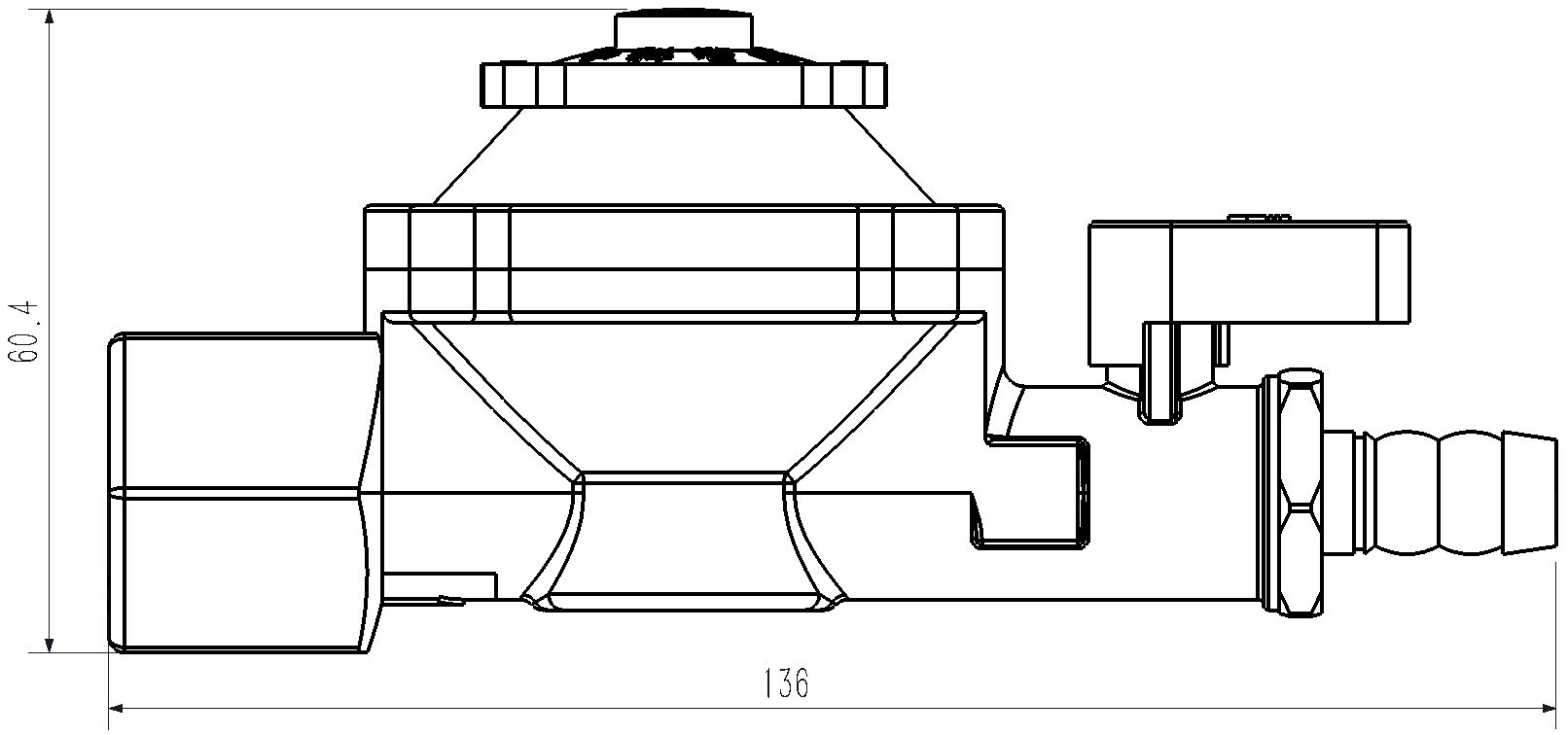

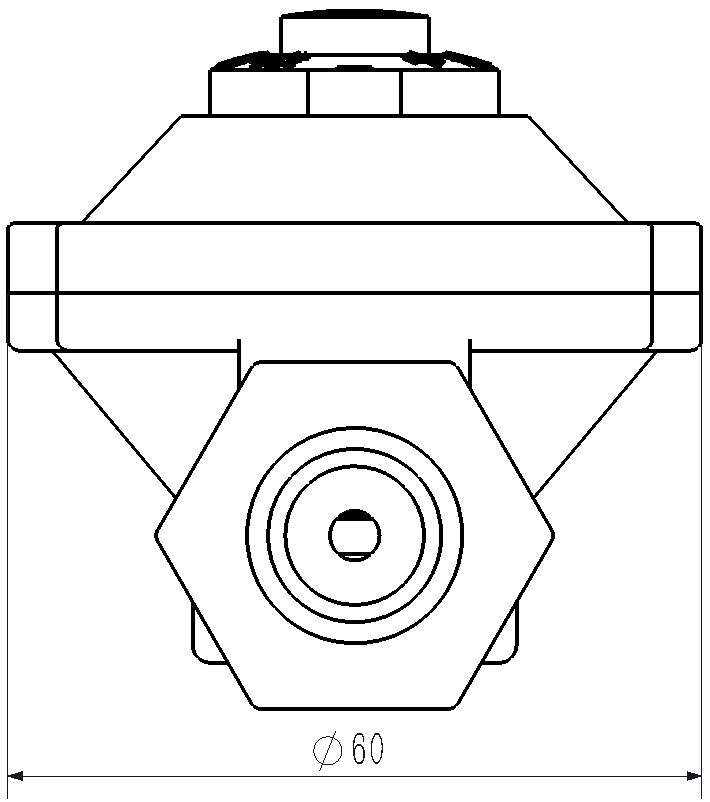

Imininingwane Yesakhiwo