I-Valve Ezivalayo Yepayipi Yegesi Enekhava Yokuvala

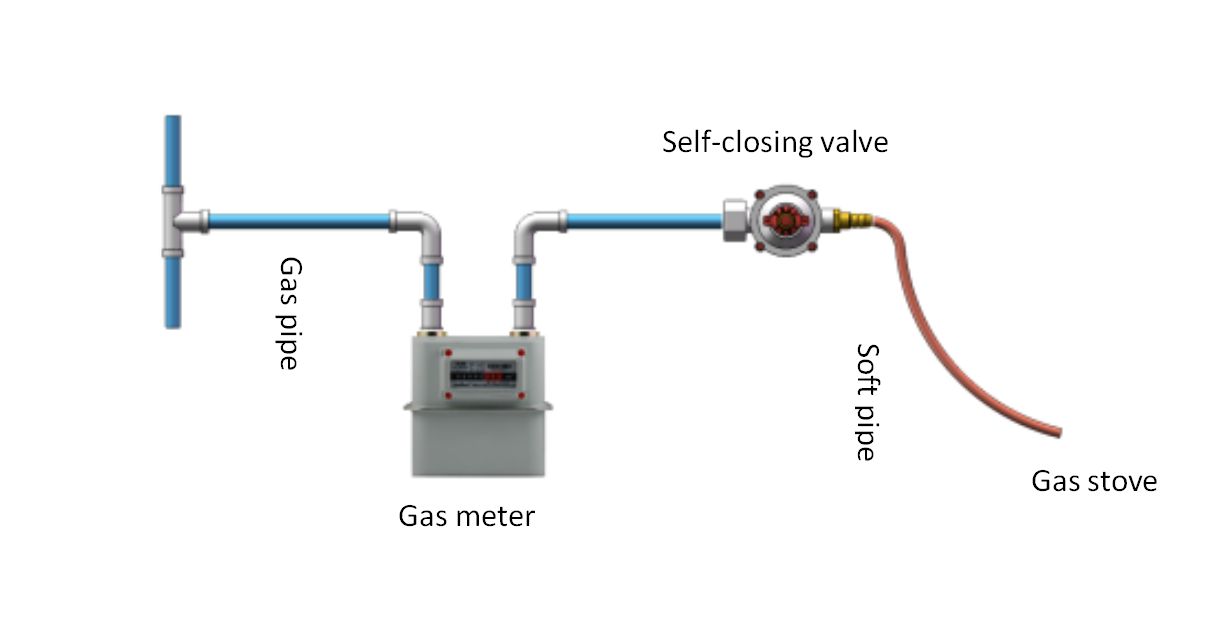

Indawo yokufaka

Ivalvu ezivalayo ingafakwa epayipini legesi phambi kwesitofu noma isifudumezi samanzi.

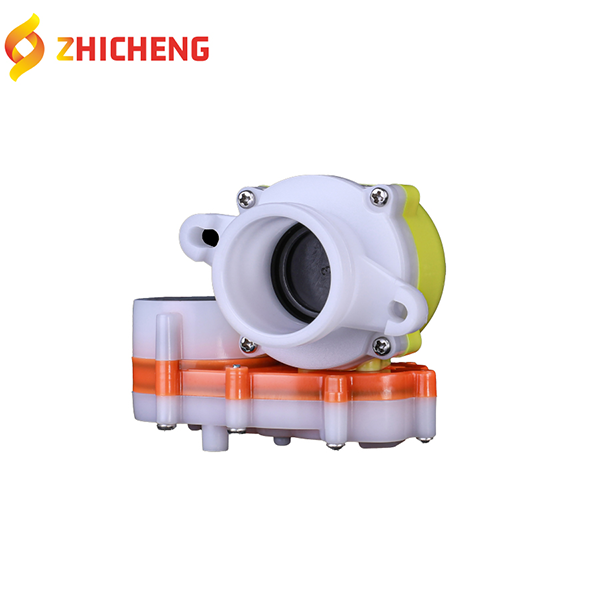

Izinzuzo Zomkhiqizo

Isici nezinzuzo ze-Pipeline yokuphepha yokuzivikela

1. Ukubekwa uphawu okuthembekile

2. Ukuzwela okuphezulu

3. Impendulo esheshayo

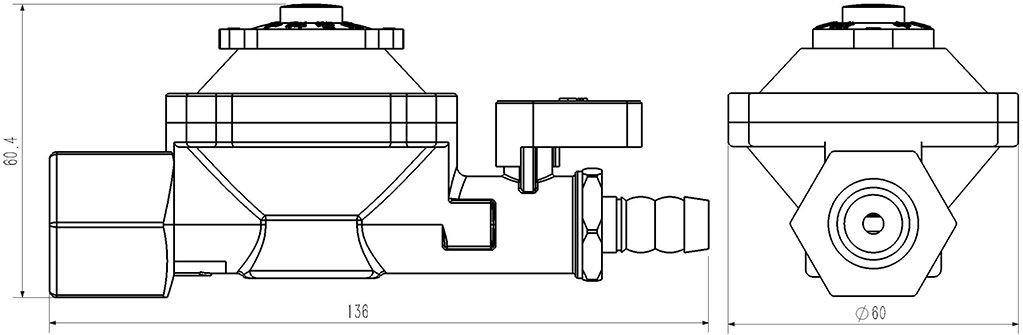

4. Usayizi omncane

5. Akukho ukusetshenziswa kwamandla

6. Kulula ukufaka nokusebenzisa

7. Impilo ende yenkonzo

Isingeniso Somsebenzi

Ukuvalwa okuzenzakalelayo kokucindezela ngokweqile

Lapho isilawuli sokucindezela esingaphambili ekupheleni kwepayipi legesi sisebenza ngendlela engavamile noma umfutho wepayipi uphezulu kakhulu ngenxa yokuhlolwa komfutho wepayipi okwenziwa inkampani yegesi, futhi udlula inani lokusetha ukucindezela okungaphezulu kwephayiphi igesi ezivalayo, i-valve. izovala ngokuzenzakalelayo ngenxa yokucindezela ngokweqile ukuvimbela ukucindezela okudalwe ukucindezela kwepayipi. Iphezulu kakhulu futhi ukuvuza kwegesi kwenzeka.

Ukuvalwa okuzenzakalelayo ngaphansi kwengcindezi

Lapho isilawuli sokucindezela esisekupheleni kwepayipi legesi singejwayelekile, phakathi nenkathi ephezulu yokusetshenziswa kwegesi, ipayipi legesi liyaba yiqhwa futhi livinjwe, ukushoda kwegesi ebusika, ukuvala igesi, ukushintshwa kwegesi, ukushintshwa, ukucindezelwa kanye neminye imisebenzi kubangela ukucindezela kwepayipi. yehla futhi iwe ngaphansi kwenani elibekiwe, I-valve izovala ngokuzenzakalelayo ngaphansi kwengcindezi ukuvimbela izingozi zokuvuza kwegesi ezingase zenzeke lapho umfutho womoya ubuyiselwa.

Ukuvala okuzenzakalelayo okuchichimayo

Lapho isishintshi somthombo wegesi kanye nesilawuli sokucindezela kwephayiphi legesi esisekupheleni-ekugcineni kungavamile, noma ipayipi lerabha liyawa, ubudala, ukugqabuka, ipayipi le-aluminium-plastic kanye nepayipi lensimbi kubhobozwa ukugqwala kukagesi, imifantu ivela ezinguqukweni zengcindezi, ukuxhuma kukhululekile, futhi isitofu segesi asijwayelekile, njll., Lapho ukugeleza kwegesi epayipini kuchichima isikhathi eside futhi kudlula inani elimisiwe lokugeleza okudlulele kwe-valve, i-valve izovala ngokuzenzakalelayo ngenxa ye-overcurrent, ukuphazamisa. ukunikezwa kwegesi, nokuvimbela izingozi zokuphepha ezingaba khona ezibangelwa ukuphuma kwegesi ngokweqile.

Umyalelo Wokusetshenziswa

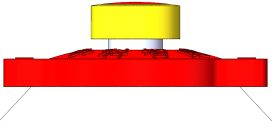

Ivalufu isimo sokuqala sokuvala

isimo esijwayelekile sokusebenza

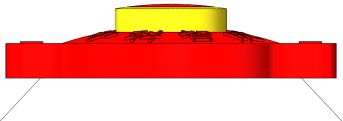

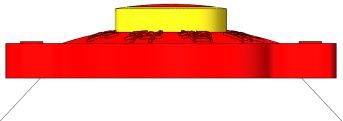

Ukuzivala kwe-undervoltage noma okwedlulele

ukuzivala ngokucindezela ngokweqile

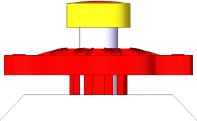

1. Esimweni esivamile sokunikezwa komoya, phakamisa ngobumnene inkinobho yokuphakamisa i-valve (vele uyiphakamise ngobumnene, ungasebenzisi amandla amaningi), i-valve izovuleka, futhi inkinobho yokuphakamisa izosetha kabusha ngokuzenzakalelayo ngemva kokuyikhulula. Uma inkinobho yokuphakamisa ingakwazi ukusethwa kabusha ngokuzenzakalelayo, sicela ucindezele ngesandla inkinobho yokuphakamisa ukuze usethe kabusha.

2. Isimo esivamile sokusebenza se-valve siboniswa emfanekisweni. Uma kudingekile ukuphazamisa ukunikezwa kwegesi komshini wegesi ngesikhathi sokusetshenziswa, kuyadingeka kuphela ukuvala i-valve manual ekupheleni kokuphuma kwe-valve. Kuvinjelwe ngokuqinile ukucindezela imodyuli yenkomba ngesandla ukuze uvale ngokuqondile i-valve.

3. Uma i-module yenkomba yehla futhi ivala i-valve ngesikhathi sokusetshenziswa, kusho ukuthi i-valve ingene ngaphansi kwe-undervoltage noma isimo sokuzivala ngokweqile (njengoba kuboniswe esithombeni). Abasebenzisi bangazihlola ngezizathu ezilandelayo. Ezinkingeni ezingakwazi ukuxazululwa ngokwazo, kufanele zixazululwe yinkampani yegesi. Ungayixazululi uwedwa, izizathu ezingaba zimi kanje:

(1) Ukunikezwa kwegesi kuphazamisekile noma umfutho wepayipi uphansi kakhulu;

(2) Inkampani yegesi imisa igesi ngenxa yokulungiswa kwemishini;

(3) Amapayipi angaphandle alinyazwa yizinhlekelele zemvelo ezenziwe abantu;

(4) Abanye ekamelweni Ivalvu yokuvala izimo eziphuthumayo ivaliwe ngenxa yezimo ezingavamile;

(5) Ipayipi lerabha liyawa noma into esebenza ngegesi ayijwayelekile (njengokuvuza kwegesi okubangelwa ukushintsha okungavamile);

4. Ngesikhathi sokusetshenziswa, uma imodyuli yenkomba itholakala ukuthi ikhuphukele endaweni ephakeme kakhulu, kusho ukuthi i-valve isesimweni sokuzivala ngokweqile (njengoba kuboniswe esithombeni). Abasebenzisi bangakwazi ukuzihlola ngezizathu ezilandelayo futhi bazixazulule ngenkampani yegesi. Ungakuxazululi uwedwa. Ngemva kokuxazulula inkinga, cindezela imojula yenkomba ukuze ubuyisele i-valve esimweni sokuqala sokuvala, bese uphakamisa inkinobho yokuphakamisa i-valve futhi ukuze uvule i-valve. Izimbangela ezingenzeka ze-overpressure autism zihlanganisa okulandelayo:

(1) Isilawuli somfutho ongaphambili wepayipi legesi asisebenzi kahle;

(2) Inkampani yegesi yenza imisebenzi yamapayipi. Ukucindezela kwamapayipi okwedlulele ngenxa yokuhlolwa kwengcindezi;

5. Ngesikhathi sokusetshenziswa, uma uthinta ngephutha imojula yenkomba, okwenza i-valve ivale, udinga ukuphakamisa inkinobho ukuze uvule kabusha i-valve.

I-Tech Specs

| Izinto | Ukusebenza | Izinga Lereferensi | |||

| Indawo yokusebenza | Igesi yemvelo, Igesi yamalahle | ||||

| Ukugeleza okulinganiselwe | 0.7 m³/h | 1.0 m³/h | 2.0 m³/h | CJ/T 447-2014 | |

| Ingcindezi yokusebenza | 2kPa | ||||

| Izinga lokushisa lokusebenza | '-10℃~+40℃ | ||||

| Izinga lokushisa lesitoreji | '-25℃~+55℃ | ||||

| Umswakama | 5%~90% | ||||

| Ukuvuza | Ukutholwa kwe-15KPa 1min ≤20mL/h | CJ/T 447-2014 | |||

| Isikhathi sokuvala | ≤3s | ||||

| Ingcindezi yokuzivala ngokweqile | 8±2kPa | CJ/T 447-2014 | |||

| Ingcindezi yokuzivala engaphansi kwengcindezi | 0.8±0.2kPa | CJ/T 447-2014 | |||

| Ukugeleza okuzivalayo okuchichimayo | 1.4m³/h | 2.0m³/h | 4.0m³/h | CJ/T 447-2014 | |